Hydraulic Test Bench

Test valves and cylinders with maximum precision.

Discover the hydraulic test bench developed by INDUSTRIAL 4.0.

Contact us now to learn more:

The hydraulic test bench from INDUSTRIAL 4.0 is ideal for testing a wide range of hydraulic valves and cylinders, with the precision of those who are true experts in the field. This test bench was designed with INDUSTRIAL 4.0’s know-how and is built using cutting-edge Parker technology.

Now you can ensure proper operation and diagnose failures in hydraulic valves and cylinders with precision and reliability.

This test bench is an original project by INDUSTRIAL 4.0, a company formed by professionals with over 20 years of experience. A true authority in industrial hydraulics.

APPLICATION

Testing of various hydraulic valves and cylinders.

BENEFITS

- Low-cost and highly reliable test bench.

- Built with high-precision Parker components, ensuring low maintenance costs.

- Offers precise failure diagnostics and verifies the quality of tested components.

- Ideal for both industrial facilities and service providers looking to elevate the standard of valve and cylinder maintenance.

Need to test hydraulic components? Contact us today and discover the advantages of using a test bench built by experts!

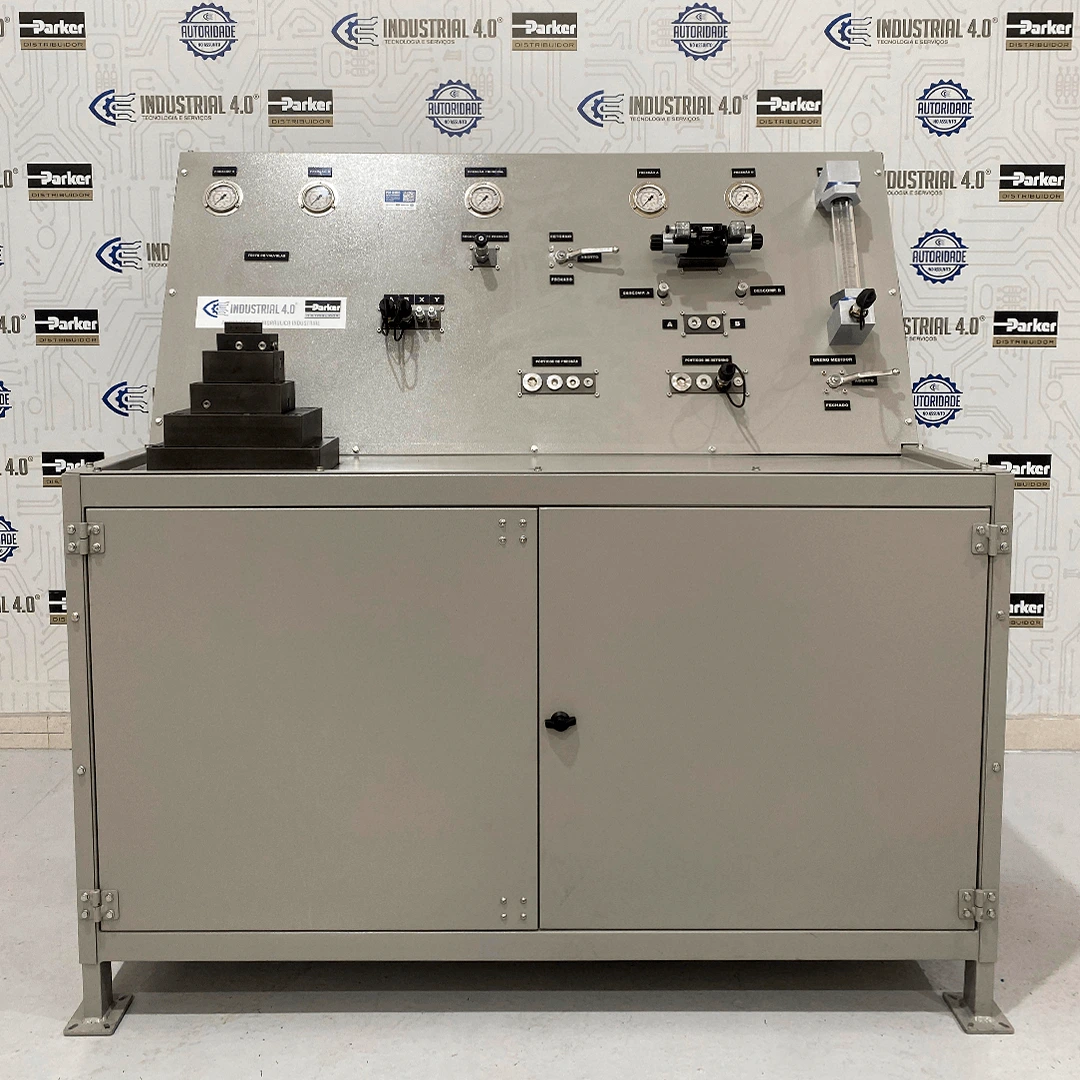

THE HYDRAULIC TEST BENCH

One of the key differentials of INDUSTRIAL 4.0’s test bench is that it is built with Parker components, guaranteeing performance, durability, and accuracy in testing.

The bench features a fully enclosed steel frame, with easy access for maintenance, two storage compartments, and braked wheels for easy mobility.

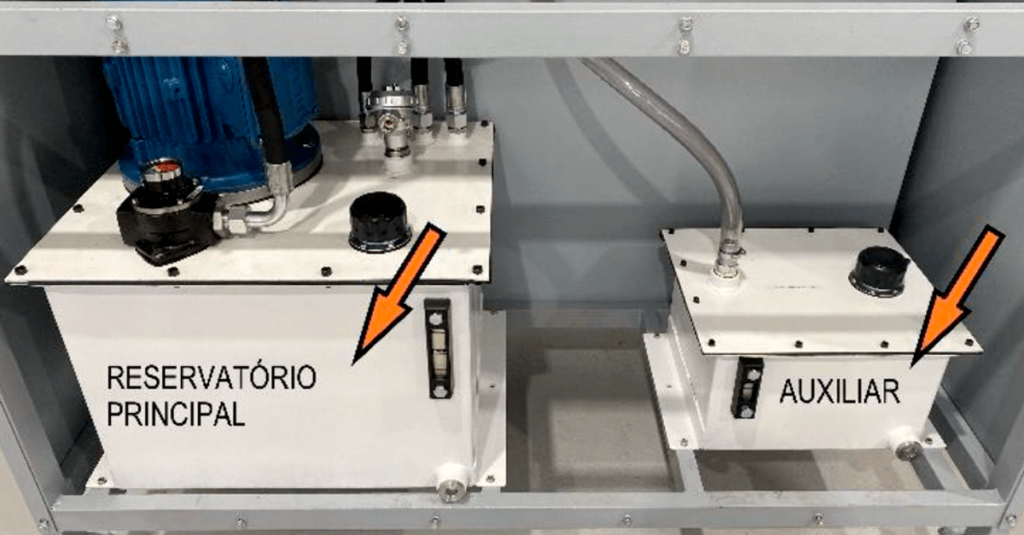

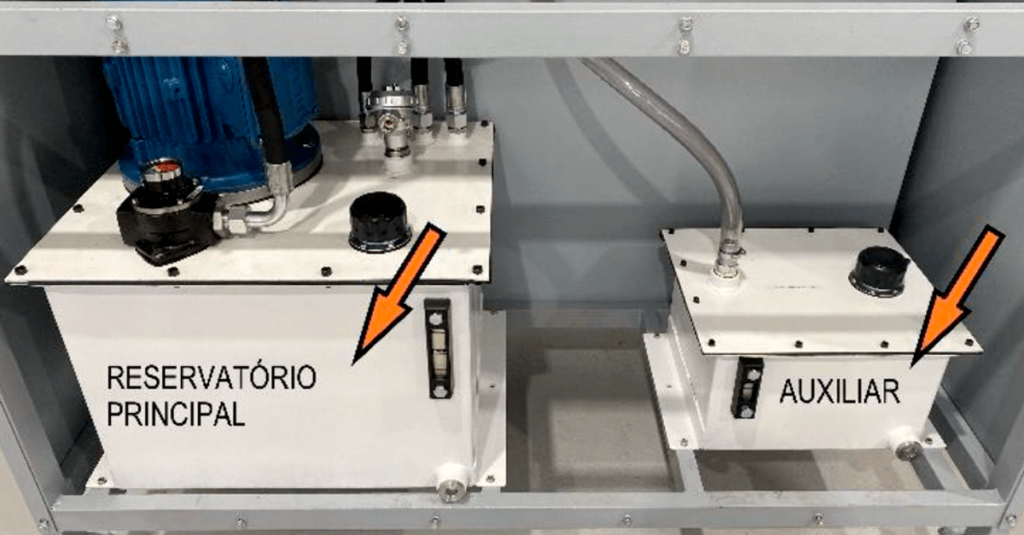

INTERNAL COMPONENTS – HYDRAULIC UNIT

MAIN RESERVOIR:

- Standard electric motor

- PARKER hydraulic pump

- PARKER coupling

- PARKER return filter for oil recirculation

- Electric level switch with two contacts (min. and max. levels)

- PARKER air breather

- PARKER oil level sight gauge

AUXILIARY RESERVOIR:

Used exclusively to collect waste oil from the test area.

- PARKER air breather

- PARKER oil level sight gauge

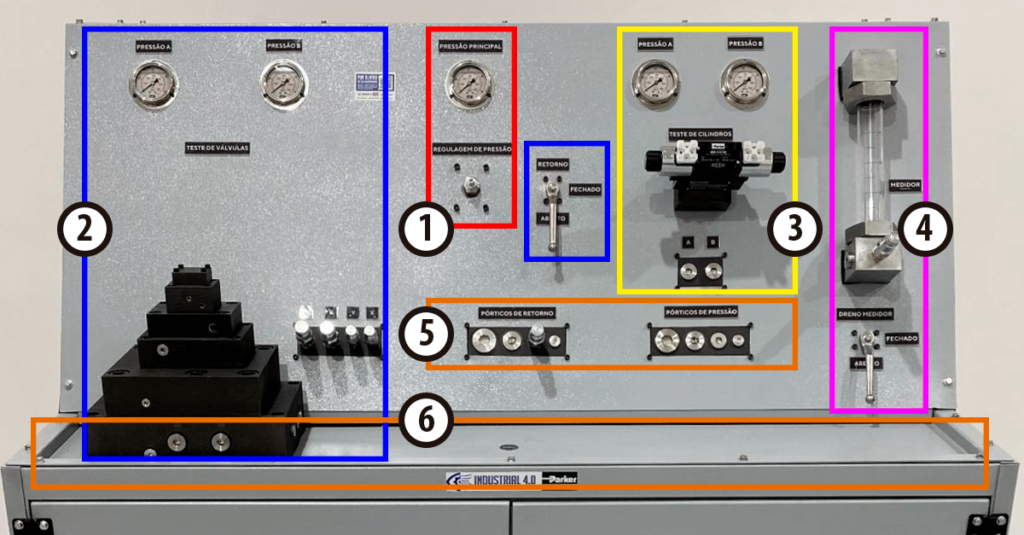

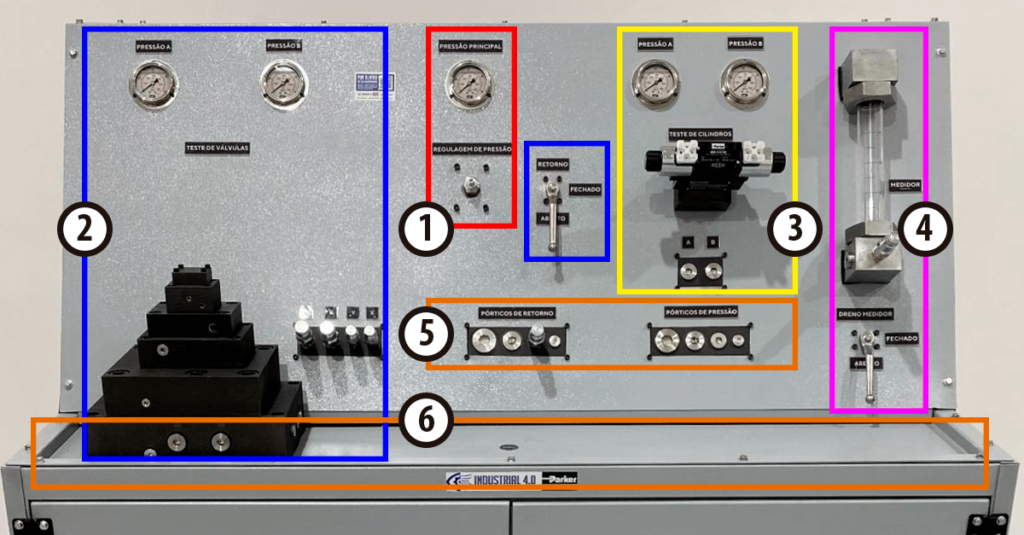

TEST PANEL

1. Main Pressure Control

Main pressure valve to regulate overall bench pressure (pump output).

2. Valve Testing

The test setup includes plates for directional valves (TN32, TN25, TN16, TN10, TN6) and a cover plate.

Pressure ports A, B, X, and Y feature quick couplers and individual pressure gauges for flow and leakage observation.

A selector valve on the return line allows switching between “OPEN” (free flow to tank) and “CLOSED” (for leakage measurement using the graduated sight gauge).

3. Cylinder Testing

Equipped with a 24VDC solenoid directional valve and a pilot-operated dual check valve.

Ports A and B (connected to the test cylinder) have individual pressure gauges for test monitoring.

4. Leakage Meter

A graduated sight gauge in milliliters (ml), with a quick coupler at its base, allows for internal leakage detection during valve testing.

5. External Test Ports

The bench provides pressure and return ports in different sizes (1″, ¾”, ½”, ¼” BSP threads) for external systems, such as non-standard valve blocks, hydraulic units, or complete assemblies.

6. Contaminated Oil Drainage

All oil from external leaks during testing or assembly/disassembly is routed to the auxiliary reservoir.

INSIDE YOUR EQUIPMENT

The test bench proudly features the “Inside Your Equipment” seal, offering fast and easy access to key information about its components and configuration.

INDUSTRIAL 4.0

With a team of professionals who have over 20 years of experience in industrial hydraulics, INDUSTRIAL 4.0 understands the real needs of the sector.

That’s why we developed this exclusive, practical, and precise test bench, ideal for testing hydraulic valves and cylinders.

Without a doubt, this test bench includes resources and features designed to make life easier for technicians and engineers working with this type of equipment daily.

In partnership with Parker, a global leader in motion and control technologies, INDUSTRIAL 4.0 brings cutting-edge technology at competitive prices, ensuring outstanding cost-benefit.

This is the foundation upon which this bench was built. The result? Contact INDUSTRIAL 4.0, ask for references, and see for yourself! We manufacture the test bench and ship worldwide.

Hydraulic Test Bench

Test valves and cylinders with maximum precision.

Discover the hydraulic test bench developed by INDUSTRIAL 4.0.

Contact us now to learn more:

The hydraulic test bench from INDUSTRIAL 4.0 is ideal for testing a wide range of hydraulic valves and cylinders, with the precision of those who are true experts in the field.

Now you can ensure proper operation and diagnose failures in hydraulic valves and cylinders with precision and reliability.

This test bench is an original project by INDUSTRIAL 4.0, a company formed by professionals with over 20 years of experience. A true authority in industrial hydraulics.

APPLICATION

Testing of various hydraulic valves and cylinders.

BENEFITS

- Low-cost and highly reliable test bench.

- Built with high-precision Parker components, ensuring low maintenance costs.

- Offers precise failure diagnostics and verifies the quality of tested components.

- Ideal for both industrial facilities and service providers looking to elevate the standard of valve and cylinder maintenance.

Need to test hydraulic components? Contact us today and discover the advantages of using a test bench built by experts!

THE HYDRAULIC TEST BENCH

One of the key differentials of INDUSTRIAL 4.0’s test bench is that it is built with Parker components, guaranteeing performance, durability, and accuracy in testing.

The bench features a fully enclosed steel frame, with easy access for maintenance, two storage compartments, and braked wheels for easy mobility.

INTERNAL COMPONENTS – HYDRAULIC UNIT

MAIN RESERVOIR:

- Standard electric motor

- PARKER hydraulic pump

- PARKER coupling

- PARKER return filter for oil recirculation

- Electric level switch with two contacts (min. and max. levels)

- PARKER air breather

- PARKER oil level sight gauge

AUXILIARY RESERVOIR:

Used exclusively to collect waste oil from the test area.

- PARKER air breather

- PARKER oil level sight gauge

TEST PANEL

1. Main Pressure Control

Main pressure valve to regulate overall bench pressure (pump output).

2. Valve Testing

The test setup includes plates for directional valves (TN32, TN25, TN16, TN10, TN6) and a cover plate.

Pressure ports A, B, X, and Y feature quick couplers and individual pressure gauges for flow and leakage observation.

A selector valve on the return line allows switching between “OPEN” (free flow to tank) and “CLOSED” (for leakage measurement using the graduated sight gauge).

3. Cylinder Testing

Equipped with a 24VDC solenoid directional valve and a pilot-operated dual check valve.

Ports A and B (connected to the test cylinder) have individual pressure gauges for test monitoring.

4. Leakage Meter

A graduated sight gauge in milliliters (ml), with a quick coupler at its base, allows for internal leakage detection during valve testing.

5. External Test Ports

The bench provides pressure and return ports in different sizes (1″, ¾”, ½”, ¼” BSP threads) for external systems, such as non-standard valve blocks, hydraulic units, or complete assemblies.

6. Contaminated Oil Drainage

All oil from external leaks during testing or assembly/disassembly is routed to the auxiliary reservoir.

INSIDE YOUR EQUIPMENT

The test bench proudly features the “Inside Your Equipment” seal, offering fast and easy access to key information about its components and configuration.

INDUSTRIAL 4.0

With a team of professionals who have over 20 years of experience in industrial hydraulics, INDUSTRIAL 4.0 understands the real needs of the sector.

That’s why we developed this exclusive, practical, and precise test bench, ideal for testing hydraulic valves and cylinders.

Without a doubt, this test bench includes resources and features designed to make life easier for technicians and engineers working with this type of equipment daily.

In partnership with Parker, a global leader in motion and control technologies, INDUSTRIAL 4.0 brings cutting-edge technology at competitive prices, ensuring outstanding cost-benefit.

This is the foundation upon which this bench was built. The result? Contact INDUSTRIAL 4.0, ask for references, and see for yourself!